As the direct-to-consumer industry continues to grow, the packaging industry is experiencing a surge in demand. Paper manufacturing machines have been converted to packaging solutions to meet this increasing demand. Bridge Automation, an industry leader in automation, empowers manufacturing industries, including the paper industry, to embrace Industry 4.0 through its advanced artificial intelligence (AI) and deep analytics efforts.

The Changing Landscape of the Paper Industry

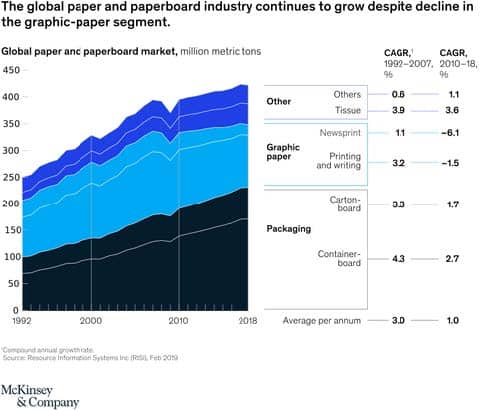

According to a McKinsey & Company study, the paper industry is undergoing one of the most substantial transformations in decades. While the demand for graphic paper declines, the need for packaging (both industrial and consumer) and tissue products is on the rise. This transformation presents new challenges for executives, such as material uncertainty and cost optimization.

THE FACTS

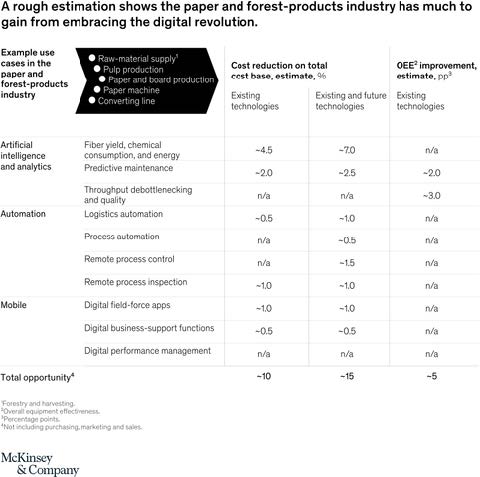

- Studies show that the industry can achieveup to 15% cost-base reduction throughdigital manufacturing.

- Forbes reveals that approximately 70% ofconsumers are willing to pay more forsustainable packaging, including compostable and paper options.

- Forbes also highlights that real-timeanalysis of shipment data can reduce costsby up to 40%.

- The pulp and paper industry, accountingfor 6% of global energy use, prioritizescontrolling energy consumption for bothcost and sustainability reasons.

Bridge Automation’s solutions play a vital role in helping the paper industry overcome environmental standards and challenges by leveraging AI and big data.

COST OPTIMIZATION AND SUSTAINABILITY

The Power of Digital Manufacturing: Moving toward digital manufacturing allows companies in the paper industry to shift away from traditional cost reduction programs towards more agile and dynamic opportunities for cost optimization.

Bridge Automation’s AI-driven solutions offer significant cost-based reductions of up to 15%, as highlighted in industry statistics.

Predictive Maintenance

Equipment Monitoring and Quality Control

If your paper manufacturing plant is having more quality issues than you expect, the problem can be identified by performing data analysis on historical data of your equipment to address problems such as overheating, or frequent operator errors on a certain process. The Bridge Automation platform is open source and can communicate with most major data historians and databases, including OSI PI, FactoryTalk, Ignition, and others.

Raw Material Management

Supplier Management: AI and ML technologies analyze data on raw material quality, supplier performance, and historical variations. This empowers manufacturers to identify reliable suppliers, establish quality standards, and make data-driven decisions for sourcing raw materials.

Environmental Compliance: Health, Safety, and Environmental Regulations

Emissions Monitoring and Control: AI and ML algorithms process real-time data from emission monitoring systems, identifying subtle trends and enabling early detection of potential compliance breaches. AI systems recommend adjustments to optimize emission control systems and reduce environmental impacts.

Sustainability Reporting and Transparency: AI and ML technologies automate the collection, analysis, and reporting of sustainability metrics. By integrating data from various sources, manufacturers can generate accurate sustainability reports, enhancing transparency and accountability.

Energy Conservation

Steam and Heat Distribution: Energy-intensive operations in the paper industry, such as heating, drying, and power generation, rely heavily on steam. Bridge Automation’s AI-powered solutions optimize steam and heat usage in real-time, reducing energy consumption. Additionally, ML-based simulations and digital twin models help experiment with process optimization before implementation, reducing energy waste.

Process Inefficiencies: AI and ML identify process inefficiencies caused by suboptimal design or operational practices. By optimizing process parameters, improving integration, and reducing production waste, energy efficiency is enhanced.

Whether it’s supplier management, demand forecasting, emissions monitoring, sustainability reporting, energy consumption optimization, or water usage management, we have the expertise and technology to provide innovative solutions. We encourage you to reach out to discuss the specific concerns and challenges faced by your manufacturing plant. Our team is ready to assess your requirements and develop tailored solutions that align with your goals.

Contact us to embark on this journey toward a more sustainable and technologically advanced future.